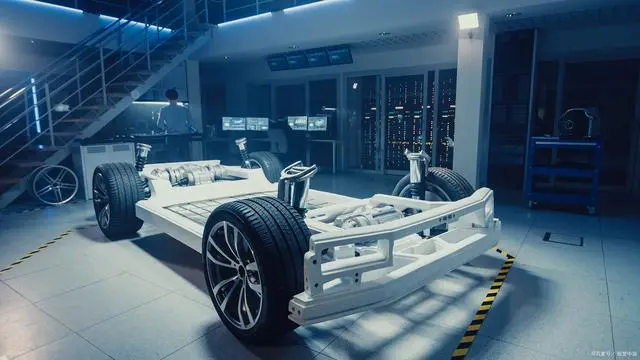

There is a focus on recycling used lithium iron phosphate batteries from new energy vehicles. A full-component green recycling line has started its work. It aims to eliminate harmful substances, recycle resources, and close the industrial loop. This will aid the sustainability of the new energy vehicle industry. The effort has significant economic benefits. Development and “overtaking on corners”.

The new energy vehicle industry is booming. There is a demand to recycle and reuse retired lithium iron phosphate batteries. This has drawn attention both inside and outside the industry. With tens of thousands of used batteries, we must recycle them. It’s vital for the environment and the new energy auto industry’s sustainability. A new production line for recycling retired lithium iron phosphate batteries has started. It uses green recycling and high-value technology. This marks a big step in lithium-ion battery recycling in my country.

Green recycling, protecting ecological safety

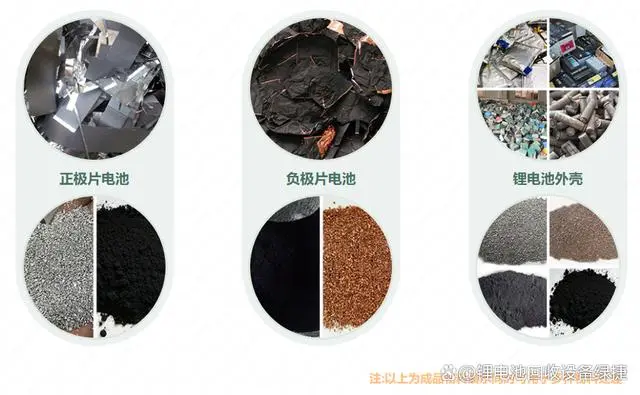

Improper disposal of retired lithium iron phosphate batteries will harm the environment. They contain toxic elements. These include fluorine, phosphorus, heavy metals, and organic substances from diaphragms and binders. However, this full-component recycling line solves those problems. This system uses advanced crushing and sorting tech. It accurately separates the battery’s components. It safely isolates and treats harmful substances. This green recycling process cuts environmental harm. It also defends my country’s new energy vehicle industry. It helps build an ecological civilization.

Efficient circulation, building a closed-loop industrial chain

A 10,000-ton lithium iron phosphate battery materials production line is another highlight of the project. It will make high-value products. This production line uses valuable metals in retired batteries as raw materials. It produces high-performance lithium iron phosphate electrodes. It does this through advanced extraction and remanufacturing processes, achieving better resource use. This innovative measure cuts the cost of making recycled products. It also breaks the limits of traditional production models. It builds a closed-loop system for the entire industrial chain of “materials-batteries-new energy vehicle manufacturing-power battery recycling.” It supports the sustainable growth of the new energy vehicle industry. It also helps upgrade our auto industry, adjust the energy structure, and reduce environmental pressure.

Significant economic benefits, helping “overtaking on corners”

The green recycling line for retired lithium iron phosphate batteries is a success. It has created both economic and ecological benefits. This recycling system has cut costs and boosted competitiveness. It is better than traditional production processes. This technology is important. It can help reduce my country’s resource shortages and high costs. It is especially urgent now due to our growing dependence on foreign metal resources. It solves the problem of people restricting resources. It also provides a solid base for the new energy vehicle industry to “overtake on the curve.” This will help my country gain an edge in the global new energy vehicle market.